The Art of Glowstar Diamonds.

Where Skill Meets Sparkle

At Glowstar Diamonds, craftsmanship is at the heart of everything we do. Our talented artisans bring decades of experience and unmatched skill to the intricate process of cutting and polishing each diamond. With meticulous attention to detail and a passion for perfection, we transform raw stones into radiant masterpieces. Our commitment to excellence ensures that every Glowstar diamond reflects the highest standards of quality, brilliance, and beauty.

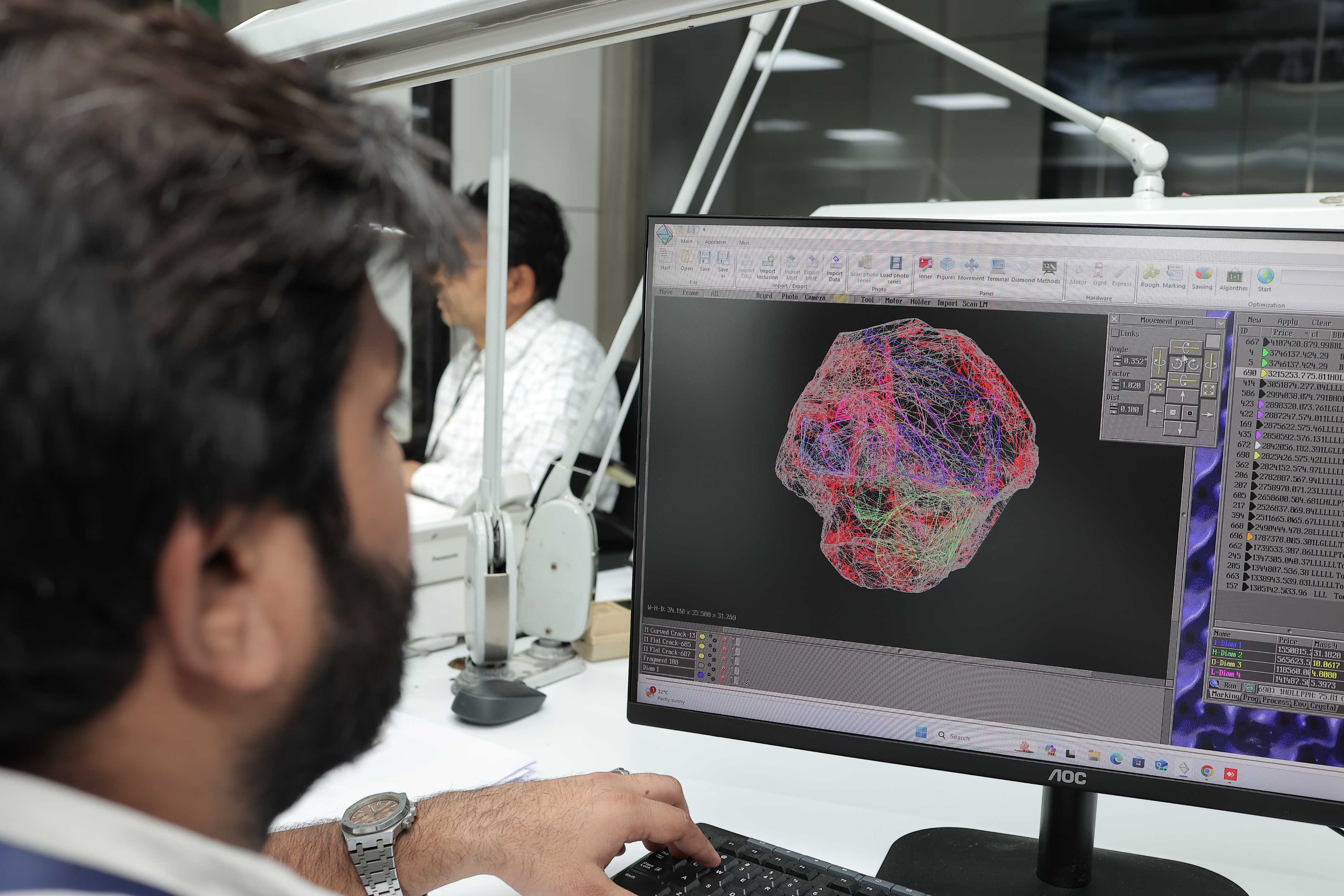

State-of-the-Art Manufacturing Facility

Precision and Innovation in Every Cut

At Glowstar Diamonds, our manufacturing facility in India is equipped with the latest technology and cutting-edge machinery. This state-of-the-art environment enables us to achieve unparalleled precision and quality in every diamond we produce. Our facility is designed to foster innovation and efficiency, allowing our skilled artisans to craft diamonds that meet the highest standards of excellence. With a commitment to continuous improvement and technological advancement, we ensure that each diamond reflects the pinnacle of craftsmanship and brilliance.

Expertise and Skilled Artisans

Mastering the Art of Diamond Crafting

Our team of highly skilled artisans brings years of expertise and a deep passion for diamond crafting to Glowstar. Each artisan is dedicated to perfecting the art of cutting and polishing, transforming rough stones into exquisite gems. Their meticulous attention to detail and commitment to excellence ensure that every diamond is crafted to exacting proportions and standards. At Glowstar, we celebrate the artistry and dedication of our craftsmen, who breathe life into every diamond, creating timeless pieces of beauty and elegance.

MANUFACTURING PROCESS

From Raw Stone to Radiant Gem

At Glowstar Diamonds, our manufacturing process is a meticulous journey that transforms raw stones into radiant gems. Combining advanced technology with unparalleled craftsmanship, each diamond undergoes a series of precise and intricate steps. From the initial cutting and shaping to the final polishing and grading, our process ensures that every diamond meets the highest standards of quality and brilliance. With a commitment to excellence at every stage, we create masterpieces that embody beauty, precision, and timeless elegance.

MANUFACTURING PROCESS

Precision, Perfection, and Trust in Every Step

The 4Cs of Diamonds

Discover the Essence of Brilliance

Understanding the 4Cs—Cut, Color, Clarity, and Carat—is essential to appreciating a diamond's true beauty and value. These universal grading criteria help determine the quality and uniqueness of each stone, guiding you to make an informed and confident choice. At Glowstar Diamonds, we excel in each of these aspects, ensuring that our diamonds are nothing short of spectacular.

THE CUT

Shaping Sparkle and Radiance

The cut of a diamond is crucial as it influences how well the stone reflects light. A well-cut diamond will sparkle brilliantly, displaying an exquisite play of light and fire. At Glowstar, our master artisans meticulously cut each diamond to ideal proportions, maximizing its inherent beauty and brilliance.

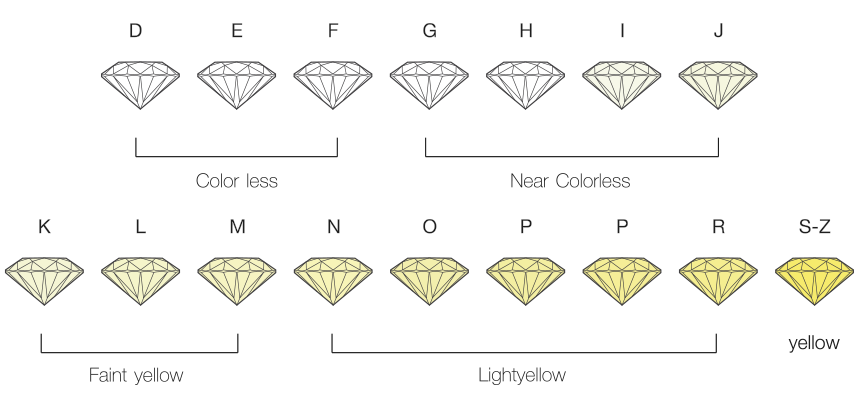

The Color

Embracing Natural Hues.

Diamond color is graded on a scale from D (colorless) to Z (light yellow or brown). The less color a diamond has, the rarer and more valuable it is. Our collection features diamonds with minimal color, ensuring a stunning, pure appearance that enhances the stone's natural sparkle.

The Clarity

Pure and Pristine Perfection

Clarity refers to the presence of internal or external imperfections, known as inclusions and blemishes. Diamonds with higher clarity grades are exceptionally rare and valuable. At Glowstar, we select diamonds with superior clarity, ensuring that each stone possesses a flawless or near-flawless appearance, free from visible imperfections.

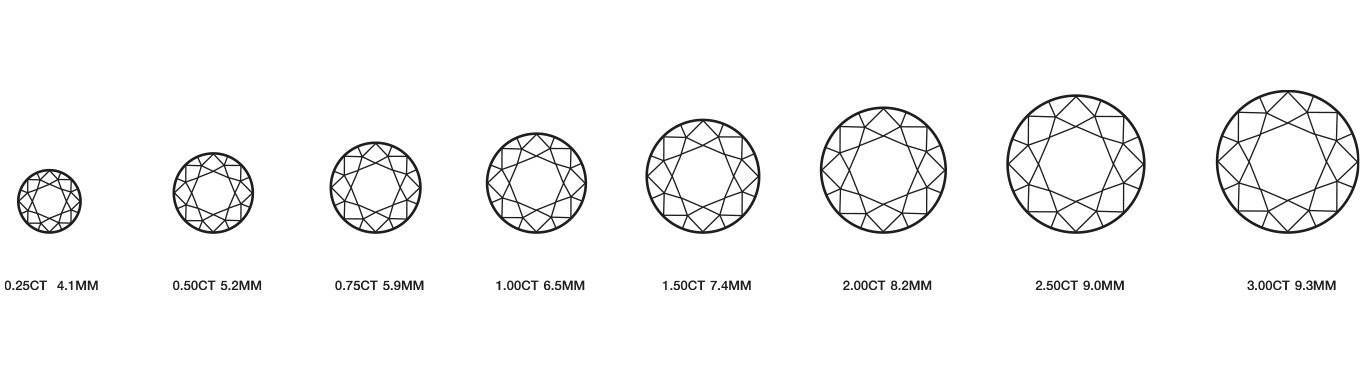

The Carat

Defining Weight and Magnitude

Carat weight measures the size of a diamond, with one carat equivalent to 200 milligrams. Larger diamonds are rarer and often more sought after. Glowstar offers a diverse range of carat weights, catering to different preferences and ensuring that every customer finds their perfect match, whether they desire a subtle sparkle or a statement piece.

CAPABILITIES

Elevating the Diamond Experience